7 Easy Facts About American Plastics Shown

What Does American Plastics Do?

Table of ContentsAmerican Plastics - An OverviewAmerican Plastics Fundamentals Explained8 Simple Techniques For American PlasticsThe Single Strategy To Use For American PlasticsWhat Does American Plastics Mean?

A little homework can assist you over time. It is challenging to judge its high quality initially glance with the look of HDPE pipeline fitting, several defects are exposed when making use of, so we can only have a correct judgment after usage. It is needed to select HDPE pipeline fittings made by a specialist maker with a great track record and online reputation.

A technological professional is vital for a great item, particularly in the manufacturing industry, since a small mistake will certainly lead to the failure of the whole project. HDPE pipes can replace concrete pipelines in field systems to save time and expense of repairing damaged or ruptured pipes. HDPE pipeline is likewise a much less pricey option contrasted to other piping products in regards to operating and setup prices.

American Plastics Things To Know Before You Buy

HDPE pipes are manufactured with strong straight or curved sections. The pipes are not breakable and can be conveniently placed into a curved location without added jointing or welding.

Chemicals resistant to HDPE pipelines can contaminate the pipe. The pipe does not function with chemicals and does not shed warmth or electricity.

HDPE pipelines are normally solid and resistant to damage triggered by exterior tons, high pressure or vibration - https://peatix.com/user/27822559/view. The pipelines can endure handling and bend also in cool weather condition. Safe eye liner HDPE internal tubing Smooth Line Pipeline Moving lining making use of roller combinations Pipeline surge Plastic pipes systems Building and construction of brand-new pipes Rust resistance, no leaking, high longevity

Warmth assimilation, while its obstacles exist, can produce strong and reputable joints. Answers: The strength and durability of HDPE can be measured by its ability to endure temperatures of around 248F in the short-term or perhaps a continuous 230F. If your application consists of gas and fluid to accessibility and increase those temperatures, HPDE piping is a dependable service.

10 Simple Techniques For American Plastics

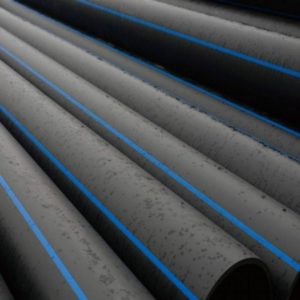

For instance, a safe and clean water line/potable water pipe is always dark with blue stripes and pipelines travelling through liquids, liquids under pressure, and procedure gases are always loaded with a yellow or black coat with yellow lines. HDPE pipeline product have actually been made use of in the basic market for over half a century and their outcomes are remarkable, developing self-confidence among producers that they are much more concentrated on HDPE pipeline options.

Times since 1991 Removal of material requirements with gauge and adjustment. In the stress fracture resistance test the cell division demands were weakened. It is reasonable to end that HDPE pipeline built today might have.

Each dimension category is created remembering the needs of stress, circulation rate, and environmental factors of the designated application. By matching the correct HDPE pipe size to its usage, designers and specialists can optimize efficiency and expand the life-span of their piping systems. Measurement and diameter are interrelated principles in the context of HDPE pipes.

The Facts About American Plastics Uncovered

As specified earlier, pipes with lower SDR worths are able to hold up against greater stress, which is an important factor to consider in the selection procedure for tasks that involve high stress or crucial applications. Texas hdpe pipe manufacturer. Picking a pipeline with an unsuitable SDR can result in system failing, safety and security risks, and pricey repair work. Selecting the right HDPE pipeline size is crucial for the success and performance of any type of piping system

Application Specifics: Tailor your pipe size selection to the specific needs of its application, whether for metropolitan, industrial, or other usages. Recognizing exactly how the HDPE pipe will certainly be made use of, the anticipated circulation prices and the stress needs are crucial. High-pressure applications could call for a pipe with a higher wall thickness to hold up against the internal stress and anxieties, while a lower-pressure, high-flow system might prioritize diameter size to decrease rubbing loss.

Getting My American Plastics To Work

Comply with these actions: Examine the see page Application: Identify the pipeline's intended use, consisting of environmental factors and solution problems. Refer to SDR: Inspect the common dimension ratio to locate a pipe that can take care of the required pressure.

Choosing the right HDPE pipeline dimension is a delicate balance between countless technological requirements and useful demands - https://medium.com/@danecoffman79701/about. With mindful factor to consider and exact calculations, you can make certain the dimension of the pipe you select will certainly offer your requirements effectively and successfully. Picking the correct HDPE pipeline dimension is vital for system efficiency, durability, and cost-effectiveness

Recognizing these elements will make sure optimum performance and compatibility throughout your piping system - custom hdpe pipe manufacturing Midland TX. The awaited flow rate or volume of the liquid being delivered is one of the key factors in pipeline size selection. A pipe that is also little can limit flow, triggering stress loss and potential obstructions, while an overly big pipe may lead to unneeded expenditure and reduced system effectiveness